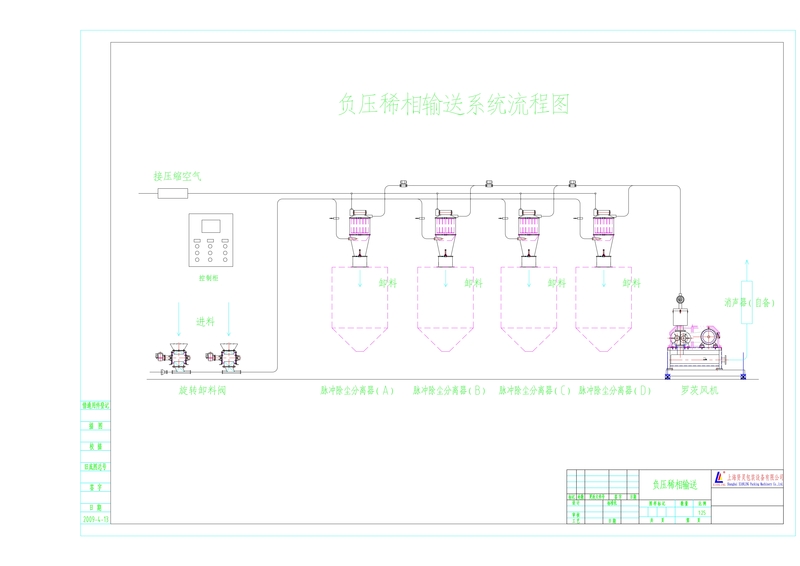

Introduction to pneumatic conveying system of negative pressure

Introduction to pneumatic conveying system of negative pressure

- Detail

- Parameters

Details:

A. Overview:

When the gas pressure is lower than atmospheric pressure, it is called negative pressure suction conveyance; Suction conveyance with negative pressure is the earliest practical application, the most reliable and mature conveyance method in engineering history.

B. Characteristics of the negative pressure system:

1. Good environmental protection reliability, the dust in the pipeline will not leak to the environment;

2. Low requirements for equipment manufacturing and maintenance, and strong operability of workers.

3. Low pressure (vacuum degree), high safety;

4. The gas (generally gas) is taken from the atmosphere, and the temperature of the gas is the local temperature at that time, which is particularly suitable for heat-sensitive materials;

5. The transportation is continuous or intermittent, and there is no accumulation in the pipeline;

6. Easy to achieve multi-point feeding and multi-point unloading conveying engineering objectives;

7. Gas power sources are generally centrifugal fans and Roots fans (pumps) with long service life;

8. Suitable for short distance transport, generally no more than 100m; It is especially suitable for conveying in the process.

9. Strong adaptability to conveying materials, powder materials and particles can be transported smoothly.

C. Operating principle of the system:

Roots vacuum pump is generally used as the power source for negative pressure suction pneumatic conveying. The pipeline and tank are pumped into a certain vacuum state, which facilitates the air inlet to form a two-phase flow between material powder and gas under the action of atmospheric pressure, and then the pipeline is fed into the separator. Two - phase flow in the separator because of filtration equipment and gravity, so that the material and gas separation, gas discharged into the atmosphere.